top of page

GTSCIENTIFIC AND MANUFACTURING LLC

-

CNC MACHINING AND MANUFACTURING

-

Honolulu, HI, Est 2017

-

Cage Code: 9USY1

Out of FV4 vises. Working on making a new iteration, maybe 2025...

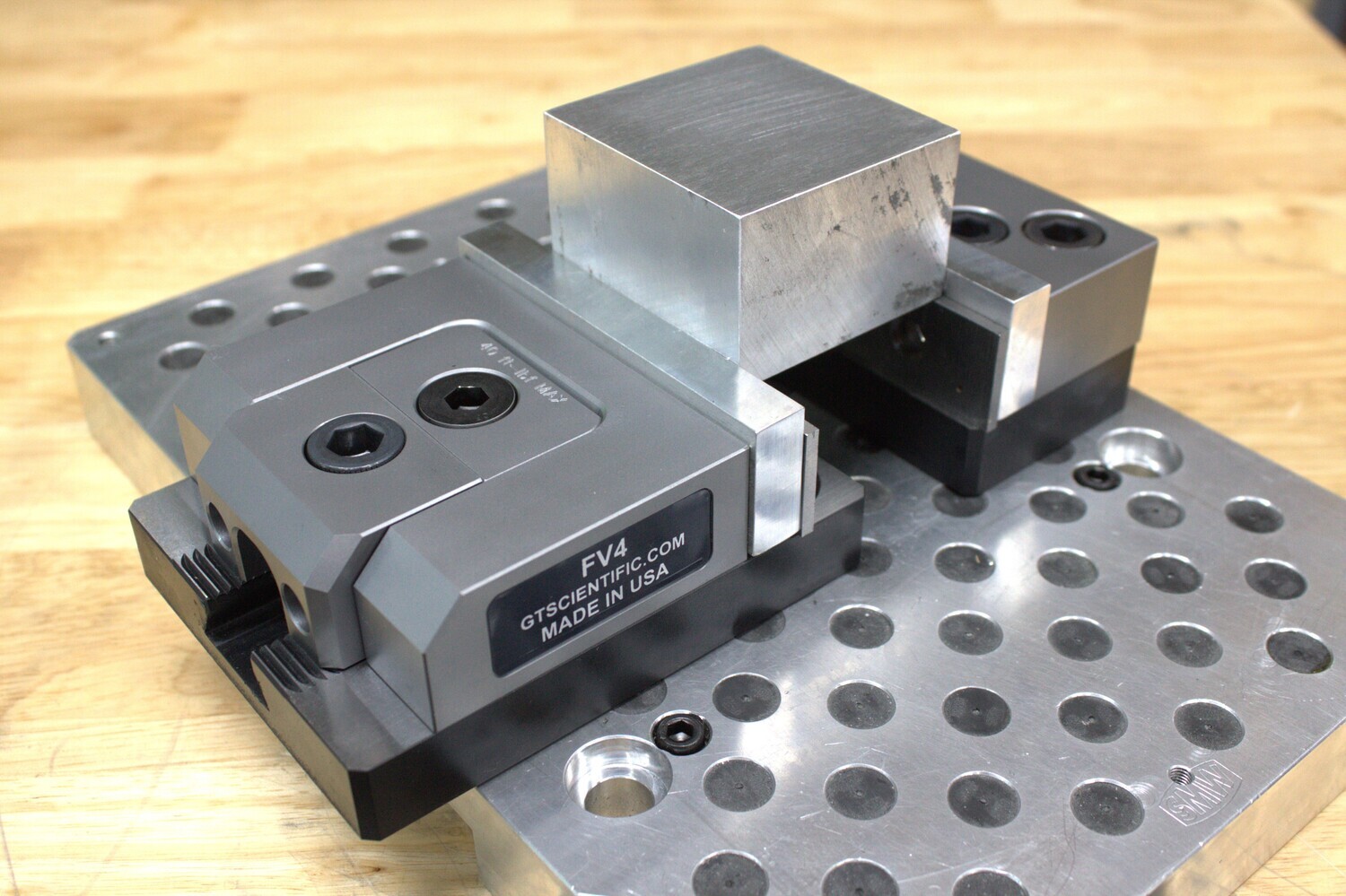

FV4 4" Fixture Vise

$399.00

Sold out

Sold out

Product Details

FV4 Compact 4" Fixture Vise.

Features

- 100% steel construction

- Hold parts larger than conventional vises

- Moving jaw is spring loaded so you don't have to retract the jaw by hand. It also preloads the jaw into the base, preventing ingress of chips.

- Serrated teeth allow for semi coarse position (travel range of 1.7"). This means you have to unbolt and adjust less when setting up.

- The wedge itself has a travel range of 1/8" (for final clamping)

- Compatible with fixture plates with 1.25" bore/thread spacing (SMW, Tosa Tool (wide body bases only), etc)

- High stress components made from 4140 PH high strength alloy steel

- Ground faces. It is designed to be a reference in Z for parallels or soft jaws. Bases are also ground to 0.750" so that long work pieces can be held on multiple vises.

- Base is made from 4140 alloy steel and hardened to Rockwell C 40+.

- Includes a standard bolt pattern for soft jaws (the same as a Kurt DX4)

- These may be upgradeable with a low profile pneumatic/hydraulic autocloser in the future

- Jack screws included (to make it easy to remove any components with pins)

- Made in the USA

- Clamping force:

- 1600 lbf @ 20 ft-lbs

- 3200 lbf @ 30 ft-lbs

- 4400 lbf @ 40 ft-lbs (nearly identical to a Kurt DX4)

Comes with the following

- FV4 Fixture Vise

- Pair of 1.2" tall, 4" wide, 0.75" thick aluminum softjaws

- 3/4" long 1/2" diameter dowel pins for the fixed jaw to fixture plate interface.

Basically, a vise that is ready for use right out of the box!

Replacement parts will be listed soon (although no one has asked me for any yet, but I understand service is nice to have).

Save this product for later

FV4 4" Fixture Vise

Display prices in:

USD

bottom of page